Do You Know What Exterior Cladding Panels Are?

Nowadays, when people buy real estate, they will attach great importance to the construction quality of the building, and several factors generally determine the construction quality. One of the critical aspects is whether the quality of the construction materials is good. Construction materials determine the stability and service life of a building and its value.

Nowadays, the application of exterior cladding panels in exterior cladding is widespread. So, what is exterior cladding panels? What are the advantages of exterior cladding panels? What scenarios are exterior cladding panels generally used in? How to install exterior cladding panels? And how to maintain exterior cladding panels? George Panel, as the top plastic wall cladding manufacturer in China, we will introduce exterior cladding panels to you in detail from the above aspects.

I. What is exterior cladding panels?

Exterior cladding panels are an artificial fiber cement board produced by George Panel. Exterior cladding panels is one of the categories of exterior wall cladding.

The raw materials used by exterior wall cladding are composed of high-purity quartz powder, high-grade cement, high-purity slaked lime, plant fibers and other minerals. After the raw materials are stirred and mixed according to the proportion of silicon and calcium, they are copied to make embryos, and then after one day of high-pressure steam curing, the board silicon calcium reacts to synthesize ‘tobermorite’ and hardens.

From raw material processing to semi-finished product processing after autoclaving, every process is strictly controlled to ensure that the market provides fashionable and beautiful exterior wall cladding with stable and excellent quality. After steaming, the exterior wall cladding will become particularly beautiful after color spraying, which is fashionable and durable.

The exterior cladding panels specifications produced by George Panel are 190mm*3000mm, 200mm*3000mm, and the thickness is 8mm. There are four main exterior cladding panels, including southern pine, northern pine, ash tree pattern, and oriental fir pattern. At the same time, exterior cladding panels have four spraying processes, namely natural color, one color, two-tone color, and antique wood color. Exterior cladding panels’ unique wood grain structure combined with wall panel design will make your house classical and elegant.

II. Features

1. Environment friendly

Exterior wall cladding is a 100% non-asbestos product. During use, our board will not produce any toxic gas and radiation.

2. Fireproof

Exterior wall cladding is fire resistance material. When a fire happens, not only the place occurs the fire, but also the place fire spreads to will be damaged and will bring loss, therefore, the fire resistance of the outer wall is very important. Exterior wall cladding is with excellent fire resistance character. In addition, it won’t cause crack and stratification after the fire.

3. Waterproof

Exterior wall cladding is with good waterproof feature. The board can guard against farthest the wall absorbs the water to avoid the wall becoming moisture

4. Anticorrosive

Exterior wall cladding is without any growth condition for fungus, and it will not be mildew in any circumstance.

5. Resistant to insect and termite

Under 11 MPA steam curing, the exterior wall cladding is hardening. Its own structural property decides that the insect and termite cannot survive on the board.

6. Heat insulation and sound insulation

Exterior wall cladding is with good sound and heat insulation.

7. Lightweight & high strength

The wall, hang ceiling or other structural parts, which is made of board and profile, when using the exterior wall cladding, will be with superiority of lightweight and high strength.

8. Easy working

The installation of the board is dry construction, which is fast It can be installed with the ordinary woodworking tool. The board is easy to be processed.

9. Easy decoration

Various decorative processing can be made for the board surface, such as coating materials or all kinds of adhesive.

10. Small deformation coefficient

The materials of exterior wall cladding are cement, quartz flour, natural xylem fiber and other minerals. Under a high-temperature autoclave, the calcium from the cement and the silicate from the quartz flour will react to form a new crystal ‘tobermorite’. It will harden within 24 hours after molding, therefore the shape of the board is steady and the deformation coefficient is small.

III. Application scenarios

Because exterior cladding panels have wood grain and characteristics suitable for outdoor decoration, they are often used for exterior cladding in garden landscape design and architecture. Usually, the building is matched with exterior cladding panels, combined with wall panel design to create a classical and elegant atmosphere.

IV. Installation guide

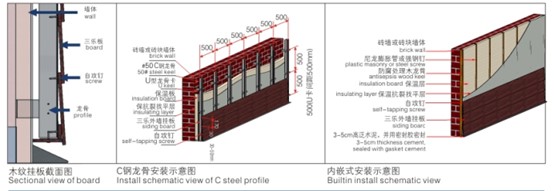

1. Guide of installation for keel fixing

(1) Check the wall which is going to be installed is even or not and cleat away from the fraise.

(2) Find out the wall base plane and then make marks on the wall by snapping the lines to make preparation for installing the keel.

(3) Put and fix the keel. We can use 50# steel keel or 25*3cm wood batten as the keel. The keels should be fixed on the wall in a vertical way with 60cm distance, which fixing accessories can be steel screw or aerated concrete plug. If using the wood batten as keel, it must be antisepsis wood, or the wood has through antisepsis treatment with impregnating fluid or asphalt. It must use reinforced Keel around the gates and windows.

(4) Fix the first board from the bottom by using a shooting screw of 3.5cm length self-tapping screw. Please attention that when using the self-tapping screw, it must use the twist drill to drill the hole previously and strike the nail head into 0.5-1mm of the board face. The nail head must be through antisepsis treatment and be rubdown by putty. The distance between the nail hole and board edge can’t be less than 1.2cm (1.5cm is the best). The distance between the nail hole and two cross sides should be 2cm.

(5) Use the same way to install the second board and the rest boards (the lapping area for up and down boards is 2.5cm). Please pay attention that when the wall width exceeds the board length, the joggles of two same level boards should be on the keel and can’t be jointed in the air.

(6) Keep 3-5mm seam for the horizontal board joint. After finishing fixing according to the requirement, the worker can use the urethane rubber (PU25) or ceramic adhesive to do the joint treatment. The joint for one side of the board and inner or exterior angle should be closed naturally and leaves a proper seam for using the adhesive to seal the joint. After installing the last top board, people should use the rubber or ceramic adhesive to seal the joint between the board and the top cornice to reach the purpose waterproof.

(7) When installing the board beside the doors and windows, people should cut the corresponding shape board with the doors or windows and use the ceramic adhesive to seal the joint to avoid the straight joint.

(8) The joint between the two adjacent boards (inner and exterior angles) should be binging off. The most common ways are joint of the 45-degree angle of chamfer and using the corner to close. When closing the inner angle, people only put the adjacent two boards as 90-degree perpendicularity and seal the joint with adhesive.

(9) Alter installation, and people should use the clean brush or towel to clean the power or greasy dirt and then paint the board. Acrylic acid is the best painting material.

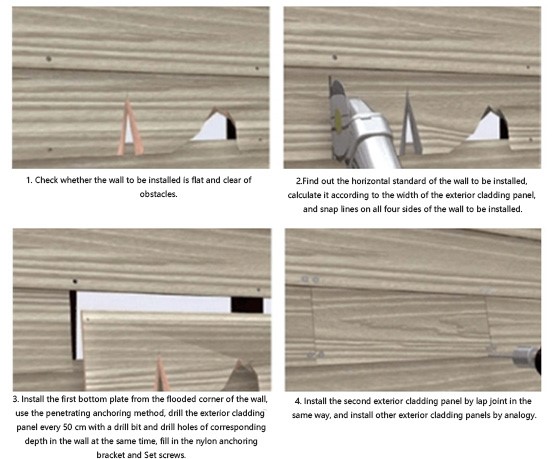

2. The non-keel fixed installation method

(1) To check whether the wall is smooth and remove the obstacles from it.

(2) Find out the basic level, calculate and snap the line around the four sides based on the width of the siding board. (The line means the horizontal spacing line).

(3) Install the same method to install the second siding board (The distance from the up and down board is 2.5cm). Use the same method to install other kinds of siding boards.

(4) Use the same method to install the second siding board (The distance from the up and down board is 2.5cm). Use the same method to install other kinds of siding boards.

V. Maintain

Exterior cladding panels are very economical and convenient, different from others. When the damage or cracking happens on the exterior siding board. You need to cut down the broken part and change the exact size of the board, and no need to change the big size.

The above is a detailed introduction to exterior wall cladding. After reading the above, I believe that everyone is already familiar with exterior wall cladding. If the outdoor exterior cladding wall panel design needs to use, it is also perfect to know it. I hope that the George Panel’s introduction to exterior wall cladding can help readers and friends.

Quick Quotation