Installation Methods of Different Wall Panels

I. What are the main wall decoration materials? And how to install it?

*Notice:

Before any wall material is installed on the wall, the flatness of the wall must be treated.

1. Wallpaper

Wallpaper is an ideal interior wall decoration material, which can be selected flexibly. Wallpaper is based on paper, coated with plastic preparations, and attached to the wall with glue. Its hygroscopicity and air permeability are poor, which is one of its drawbacks. Therefore, some people are not happy to use it, and use paint instead. Most people abroad still use wallpaper and wall coverings. Japanese people mainly use wallpaper and are not interested in paint. Today’s popular flame retardant wallpaper is still a decorative hot spot.

The lamination of wallpaper has higher requirements on the flatness of the wall. Therefore, before sticking wallpaper, the wall must be treated to make the wall smooth, flat, dry and solid, free from unevenness, dirt and peeling. Apply glue on the back of the cut wallpaper, fold the glued side for 5 minutes after coating, let the glue completely penetrate the bottom of the paper, and then paste it. You can paint several wallpapers at a time and paste them in sequence. Finally, use a scraper to gently scrape the wallpaper from top to bottom, from the middle to the surrounding, squeeze out the bubbles and excess glue, and make the wallpaper flat and close to the wall.

2. Wall fabric

There are three types of wall fabrics: fiberglass printed wall coverings, decorative wall coverings and non-woven wall coverings. Its advantages are firmness, breathability, flame retardant, noise reduction and sound absorption.

The disadvantage is that its price is higher than that of wall fabric, and most of them are imported products, which need to be used in conjunction with luxury room decoration to strengthen the artistic taste.

First of all, first smooth the flatness of the wall, measure the length of the wall, from one inner corner to another inner corner. Then cut the wall covering according to the length of the wall, leaving a reserved position of about 5 cm. Then apply the glue evenly to the wall. Finally, glue the wall covering to the wall. Special reminder, the wall covering is different from the wallpaper. The glue when pasting the wall covering is painted on the wall, not on the wall covering. The wall fabric cannot be wet or glued.

3. Paint decoration

The interior wall decorative paint is used, and the film-forming substance is used to bond it to the wall, and the dry film thickness has a certain protective and decorative effect on the interior wall. There are three types of solvent-based paint, water-soluble paint and latex paint paint. It is characterized by non-toxic, breathable, flame retardant, no peculiar smell, cheap price, mature and firm, bright and clean appearance, and is widely used.

First, flatten the wall first, then repair the uneven position of the wall by scraping the putty twice, then apply the primer and brush evenly, and then make repairs, pay attention to be sure to polish it flat, and then you can paint work now.

4. Tile

The inner wall tiles are used to paste the wall with adhesive, which is clean, hygienic, non-vacuuming, and easy to clean. Mostly used to decorate walls in kitchens and bathrooms.

First of all, first smooth the flatness of the wall, then spread the cement mortar on the wall, then smear the cement mortar on the back of the tile, and then spread the tile evenly on the wall, you can do this and so on, to paste the next tile.

5. Mosaic

Mosaic is the smallest wall decoration material. It is very fashionable, has strong pressure resistance, low water absorption, acid and alkali resistance, impermeability, firm and beautiful quality, and is mostly used for balcony and bathroom decoration.

First of all, first smooth the flatness of the wall, and then use the grout to smooth the wall before laying, and then use the same kind of grout just used to grout the back of the mosaic, and fill the grout as soon as possible. The mosaic is neatly paved in the direction of the trademark arrow and patted with a flat plate.

6. Stone

Stone used as wall decoration materials are mainly divided into two categories: natural and artificial.

The natural veneer stone used for interior wall decoration is marble; the artificial veneer mainly includes artificial marble, prefabricated terrazzo slab, etc. The wall decorated with stone looks elegant and magnificent.

There are three ways to install the stone on the wall. The first is dry hanging, which is fixed on the wall with bolts. Then slot a piece of stone, fix the stone with a T-shaped frame, and then fix the T-shaped frame and bolts together. There are certain examples of such a marble wall and the wall itself, but the fixation is good. The second is wet stickers. First lay a layer of steel mesh on the wall, and then use concrete wet paste. The third is to paste directly. The direct paste method is not suitable for the bathroom, because the bathroom is mostly light-weight wall, the deformation is large, and the bathroom is often wet, and the glue is easy to age and cause accidents over time. In addition, due to the large deformation of the lightweight wall, if the wall is deformed after gluing, the stone will also change, causing hidden dangers.

7. Solid wood

Solid wood wallboard is a new type of decorative wall material developed in recent years, using solid wood as the base material. It can replace both wallpaper and wall materials such as wall tiles, so it is widely used. Solid wood wallboard has the advantages of light weight, fire prevention, moth resistance, simple construction, and generous shape.

First, show the plan we need to set on the drawing, and then start to lay out the holes, use stainless steel expansion bolts to inlay the special keel for solid wood wall panels on the wall, pay attention to be firm enough, and the distance between them is the best It is about 60cm, and then use angle head bolts to fix the solid keel on the special keel, and then put the solid wood wall panel on the solid keel, which must be fixed well.

8. Diatom mud

Diatom mud is an environmentally friendly decorative wall material for interior walls that uses diatomite as the main raw material. It is not only decorative, but also functional. As a novel decorative material in the home improvement market in recent years, it is deeply loved by consumers because of its natural materials, environmentally friendly and healthy materials.

First, use a small spatula to deal with the flatness of the wall, add an appropriate proportion of water to stir the diatom mud, and then use it after the viscosity is suitable. According to the on-site climate conditions, it is advisable that the surface is not sticky to the hand, and the bottom condition is filled with materials, and then painted a second time, the thickness is about 1.5 mm, and the total thickness is between 1.5 mm and 3 mm. Most people like flat diatom mud, and if you like the properties, you can grasp the boring moment according to the actual environment and dry conditions, and make texture patterns according to the construction method.

9. WPC wall panel

A WPC wall panel is a kind mainly made of wood as the basic material, thermoplastic polymer material and processing aids, etc., mixed evenly and then heated and extruded by mold equipment. High-tech green environmental protection new decorative material, which has both the properties and characteristics of wood and plastic, is a new composite material that can replace wood and plastic.

For different types of WPC wall panels, the installation methods are also different. In general, there are roughly three differences, namely whether a keel is required, whether there is a slot at the splicing, and whether the fixing method is screw or glue. We will focus on the installation methods of different wall panels in the second major point.

II. How are the different types of WPC wall panels installed differently?

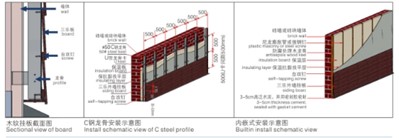

1. WPC Great Wall board

The f50 great wall board and the F75 great wall board can be installed without the keel, while the F45 great wall board needs to be installed with the keel, and the keel installation is efficient and labor-saving.

The first step is to weld the steel frame, the second step is to install the keel, and then the keel is fixed on the steel pipe with screws. The machine cuts off the excess part, and the fourth step is to wrap the edge and close the mouth. When buying the WPC interior wall panel, the WPC wall panel company has a matching edge wrapping. The large screws on the side do not affect the appearance, and the effect is very good after wrapping.

2. WPC Exterior Cladding Panels

The first is to install the keel, choose a wood-plastic keel, drill a hole in the keel and the wall, and then drive in the nails. After the keel is fixed, the wood plastic composite wall cladding can be installed.

The installation of the wood plastic composite wall panel does not require accessories. Yes, you can directly fix the WPC outdoor wall panel with screws, the screw heads will not be exposed after installation, and the appearance will not be affected. The splicing interface is designed with male and female grooves. It is installed on the female groove with flat head screws. One piece is buckled, and the installation of the exterior WPC wall panel is very convenient. The WPC wall panel design of the male and female grooves can effectively prevent rainwater from infiltrating.

3. WPC Ceiling

Before installing the WPC ceiling panel, first make the hanging bars, fix the upper keel, fix the keel, apply nail-free glue under the keel, and cut the size.

Fasten the edge of the female groove with screws, install the next piece in sequence, close the last piece, and apply some more nail-free glue on the edge, because the last piece of WPC false ceiling cannot be clamped, so simply tap a few points with a straight nail gun.

4. Wall Mounted Headboard

Wall mounted headboard is composed of bottom plate, sponge interlayer, decorative surface leather and shaping strip. The custom background wall panel consists of base plate, sponge interlayer, veneer leather and shaping strip.

The installation methods of the soft wall and the hard wall in the customized background wall are different and the same. The same is that both need to be plywood as the bottom plate before installation. The difference is that the soft wall needs to be sandwiched between the fabric and the bottom plate. The hard wall is the fabric directly attached to the bottom plate.

5. WPC Wall Cladding

First, measure the required size of solid wood interior wall panel, then cut the WPC wall cladding with a saw, prepare glass glue and styrofoam glue, put glue on the back of the WPC wall paneling, and spread the glue evenly, then paste the first WPC interior wall panel on the wall, the clip is buckled on the edge of the mother groove, snapped into the clip, fixed with gun nails, and then inserted into the next piece of solid wood wall cladding, fixed with nails, and installed in sequence.

6. WPC Wall Panel

Apply expansion glue on the back of the WPC interior wall cladding, and attach the matching fixing clips in the mother groove of the composite wall cladding. The clips can be directly fixed with 25 steel nails. Before each WPC panel for walls is glued, first install the fixing clips, and then put on the expansion glue, and fix each wall panel in order in this way.

When encountering the position of the socket, remember to measure the size of the socket mouth, and use a sewing machine to saw the socket mouth. After installation, there will be gaps up and down, and the gap is closed with a closing line.

7. WPC Composite Board

Measure the height of the wall, determine the height of the waistline, use an ink fountain to play the line, first make a letter, fix the height of the waistline of the WPC composite board, cut the WPC cladding according to the size, put structural glue and styrofoam on the back of the WPC wall panel, align the position of the line box and insert the I-shaped strips, install the next wall panel in turn, and then fix the I-shaped metal strips to keep all the wall panels installed horizontally and vertically.

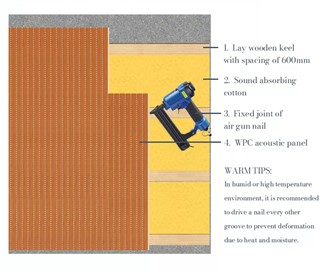

8. WPC Acoustic Panel

The first step is to mark the wooden keel, the distance between the keels is 30-40cm, and the distance between the wall and the WPC sound-absorbing panel is reserved. The second part is filled with sound-absorbing cotton; the third part, the sound-absorbing board is spliced, and the card slot is spliced. Nails and fasten the WPC soundproof panel to the keel.

The notch of each WPC acoustic panel is spliced with seams, and it is not easy to be deformed by thermal expansion and cold contraction, and has good stability. It adopts the installation method of snap splicing, which is simple, very convenient and firm.

The first step is to fix the wooden keel to make a cavity to provide space for filling the sound-absorbing cotton; the second step is to use the piercing keel to fix the buckle to increase the stability of the keel structure; the third step is to fill the sound-absorbing cotton, which can effectively Dissipate the sound energy generated by the sound; the fourth step is to fix the WPC sound-absorbing panel on the keel with air gun nails, so that the installation of the WPC soundproof panel on the wall is completed successfully.

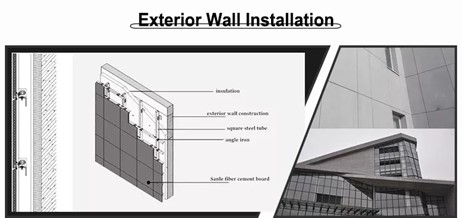

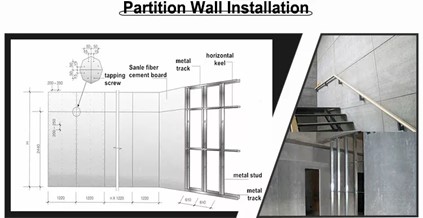

9. Fiber Cement Board

Our fiber cement boards are easy to install. It can be installed on the construction wall directly or on the stainless steel keel. Comparing with the traditional brick wall installation, it can save 50% labor cost and time cost.

*Exterior wall installation

Mounting the advance processing board on the keel according to the design drawings, and using aluminum accessories to connect the panel and keel. Hanging lightly the same level layer fiber cement boards on the keel, and then adjusting the horizontal and vertical degree of board through upper and lower steel wires. After that, checking the boards seam, whose width should be uniform according to the requirements of WPC panel design. Last, tightening the stainless steel screws on the complete set of aluminum accessories.

*Partition wall installation

The top and bottom keels are fixed respectively top floor and on floor with expansion bolts. The vertical keel should be aligned well according to the requirement with laterally supporting keel installed. Cutting the board material to the dimensions needed (about 10mm lower than wall height). Board material is fixed on keel in an anchoring seam way with tapping screw: the interval of tapping screw is generally about 200~250mm with screws sinking 0.5mm under the board face.

The expansion seam of about 4mm between boards should be kept. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously to avoid generating inner stress to make board material bucking. Before the fiber cement board is packed and fixed, glass wool or rock wool can be filled as required.

*Floor board installation

Before laying the boards, the welding seam on the top surface must be polished flat and the welding spatter must be cleared away. Keep the longitudinal direction of the fiber cement board parallel to the main beam, any edge of the board must not be suspended, a gap of 3~5mm must be left between the board and the board, and the joint between the board and the board should be located in the center of the beam. Selecting the countersunk head tapping screw, nailing on the vice-keel (Angle iron).

Drill first and then nail, nail hole should be bigger than the diameter of the nail. Nailing starts from the center of the board, and then hits outwards, and finally hits the side nails. The nailing position of the side nail should be about 20mm from the edge of the board. The nail distance is 300~600mm. The joint can be injected with silicone sealant, or mortar can be used.

III. What are the advantages and disadvantages of wall panel installation compared to the installation of other wall decoration materials?

1. Paint VS WPC Wall Panel

Advantages: Although the WPC wall cladding price is not high, painting on the wall is cheaper than interior WPC wall panel installation price and labor costs.

Disadvantages: The flatness and integrity requirements of the paint on the wall are higher than the installation of the WPC slatted cladding, because if the wall has cracks or gaps, it will have a great impact on the paint on the wall, but if the WPC interior wall cladding is installed, if the wall is not flat, you can play the bottom plate to solve the problem of incomplete wall.

2. Wallpaper VS WPC Wall Panel

Advantages: Wallpaper paste is cheaper than WPC wall panel interior installation price and labor costs.

Disadvantages: The wallpaper will use glue during the laying process, which will generate a certain amount of formaldehyde, but installing the WPC wall panel using screws and other fixing methods will not only produce no odor that will harm the human body, but also will not affect the appearance.

3. Tile, Mosaic VS WPC Wall Panel

Advantages: The installation process of tiles and mosaics on the wall is simpler than that of WPC Wall Panel, and the steps are single.

Disadvantages: The cost of primer, mortar and labor on the wall of tiles and mosaics is more expensive and more expensive than that of WPC Wall Panel; the installation of tiles and mosaics is only suitable for some walls, and it is more commonly installed in kitchens and bathrooms, while WPC Wall Panel installation is suitable for any interior wall.

4. Solid wood VS WPC Wall Panel

Advantages: Compared with some types of WPC Wall Panel installations, which require glue bonding, the base of the log siding is made of natural pure wood slats, without skins and no interlayers. The products produced from this use the least amount of glue, Installed and tasteless. If the room is decorated as a whole, there is no painting process, which solves the problem of time-consuming decoration materials and paint smell that does not evaporate for a long time.

Disadvantages: Before installing solid wood, the wall needs to be moisture-proof. Because the wood has a high moisture content, it is easy to shrink after drying and cause joint cracking. The material of the WPC Wall Panel itself has the characteristics of moisture-proof, so there is not much requirement for the humidity of the wall.

5. Stone VS WPC Wall Panel

Advantages: Compared with WPC Wall Panel, the solidity of the stone wall is very good, and the construction time is shorter; the glue is strong, and the stone is not easy to fall off after installation.

Disadvantages: Compared with WPC Wall Panel, when encountering wet walls, it is very easy to return to alkali and appear hollow on the wall.

IV. What are the top wall panel manufacturers in China? The top ten brands of wall panel manufacturers and suppliers in 2022 are announced!

The annual online voting for the top ten brands of integrated walls in China will come to an end in 2022. The annual selection of the top ten brands of China’s integrated walls has been praised by consumers and enterprises in the major home building materials industry.

The top ten brands of China’s integrated walls are jointly sponsored by China Famous Brand Network and the World Commercial Brand Management Center, and the “China’s Top Ten Brands of Integrated Walls” in 2022 have been announced:

Rank |

Manufacturer |

Headquarters |

1 |

LESCO | Guangzhou, Guangdong |

2 |

George Panel | Foshan, Guangdong |

3 |

MostHome | Dongguan, Guangdong |

4 |

MADANI | Dongguan, Guangdong |

5 |

DEGAS | Foshan, Guangdong |

6 |

WICANDERS | Qingdao, Shandong |

7 |

JILINK | Xi’an, Shanxi |

8 |

Haolee | Shenzhen, Guandong |

9 |

KOJO | Chizhou, Anhui |

10 |

SanSheng | Hangzhou, Zhejiang |

1. Guangzhou Jinfa Lvke Wood Plastic Technology Co., Ltd.

The revolutionary green environmental protection material “LESCO” is a high-tech new environmentally friendly composite material made by Guangzhou Jinfa Lvke Wood-Plastic Technology Co., Ltd. using patented technology, high-tech processed wood powder and a small amount of polymer materials. While retaining the natural woody feel of great vitality, it overcomes the fatal weaknesses of logs exposed in practical environmental applications such as water absorption deformation, mildew, cracking, warping, flammability, and vulnerability to insect pests and fungi.

2. Foshan George Panel Wood Plastic Technology Co., Ltd.

George Panel is an excellent WPC wall panel manufacturer. George Panel is specialized in ecological wood panel, Great Wall panel, ceiling, grille, sound absorbing panel and other high-grade environmental protection materials, over the years, focus on the development and production of panel industry, with the development and expansion of the enterprise, sales, design, logistics, installation and other modules of the improvement, has become a one-stop supply enterprise.

George Panel has many years of experience in the production of wall panels, and has matured and mastered the research and development technology of WPC wall panels, which is at the forefront of the wall panel industry, and can provide customers with the most innovative WPC wall panels on the market.

3. Dongguan Meijie Wooden Products Co., Ltd.

Dongguan Meizhi Wood Art Products Co., Ltd. is a subsidiary of Hong Kong United Beauty Decoration Group. Hong Kong United Beauty Decoration Co., Ltd. was founded in 1991. From a small enterprise focusing on the processing and export of woodcarving decoration accessories, it has developed into three subordinate companies. It is a group company with four major brands, spanning the three fields of building materials, home furnishing and real estate. MostHome is a one-stop customized home furnishing brand.

4. Guangdong MADANI Home Customization Co., Ltd.

Maidanyi regards Dongguan as its brand operation center in China. Medani has advanced production equipment and is a modern production enterprise with strong technical force and large factory area in the domestic custom home furnishing industry. Maidani mainly promotes solid wood customization for the whole house, and its products include solid wood doors, stairs, parapet walls, wine cellars, overall wardrobes, furniture, soft furnishings and other whole house solid wood customized home furnishing.

5. Foshan Degas Impression Wood Industry Co., Ltd.

Foshan Degas Impression Wood Industry Co., Ltd., Dejia Impression, the top ten brands of whole wood home improvement, under the Xinruncheng Group, is engaged in log doors/solid wood composite doors/wall panels/wine cabinets/wardrobe doors and whole wood furniture and other related wood companies that manufacture products.

6. WICANDERS Health Home Co., Ltd.

WICANDERS’s products are positioned as healthy boutique products, and the products it manages include floor decoration materials, wall decoration materials, health care products and other mid-to-high-end healthy household and imported floor products.

The wall decoration materials that Degao represents are: Japanese SANFOOT solid wood wallpaper, Portuguese WICANDERS cork wall panel, Italian ITALARTE art wallpaper, French FRENCHSTYLE style wallpaper and American NEXTWALL wallpaper, all products are original brand sales.

7. Xi’an JILINK Cork Flooring Co., Ltd.

Xi’an JILINK Cork Flooring Co., Ltd., since its establishment in 1998, after 14 years of deep accumulation in the industry, has successfully broken through technical problems such as the production process of cork flooring, and has achieved great success by using the rich wild oak bark resources in the Qinling area of my country. It has greatly reduced the gap between my country’s cork flooring and its international counterparts, and has also broken through the technological bottleneck of domestic cork production. The production process of domestic cork flooring in my country has reached the international advanced level, which is completely comparable to similar imported products abroad.

8. Shenzhen Haolee Log Home Decoration Co., Ltd.

Oxley Group was established in 1996. At the beginning of its establishment, the company was mainly engaged in the research and development, production and sales of log set doors. After more than ten years of development and precipitation, Oxley has grown into a company integrating log custom furniture, log set doors, and log stairs. , log suite furniture, log cabinets, log bathroom cabinets, log wall panels, log ceilings and other log home products as one of the group enterprises.

9. Anhui KOJO New Material Technology Co., Ltd.

KOJO Group has wood-plastic base material extrusion production center, there are more than 60 wood-plastic extrusion production lines, three large-scale wood-plastic door panel production lines, more than 700 sets of various types of wood-plastic extrusion molds, with an annual output of more than 20,000 tons of environmentally friendly wood-plastic materials . The finishing processing center has more than 40 cold glue coating production lines, six PUR hot glue coating production lines, and one flat coating production line. Various types of finishes are environmentally friendly new materials.

10. Zhejiang Sansheng Home Furnishing Co., Ltd.

Since its establishment, the Sansheng Meijia brand has adhered to the leading product concept of “natural wood, tailor-made, luxurious and elegant”, based on perfect original design masterpieces and imported production equipment, and exquisite production technology to provide various domestic decoration products. Personalized overall woodwork in a variety of styles. The annual sales of each of the company’s directly-operated stores have exceeded the 10 million mark, and the products have been sold to major cities in China. The raw materials of the products are taken from the wood imported from Europe, America, Africa, Southeast Asia, and other countries.

If you have any questions about WPC wall panel installation, you are welcome to consult George Panel, George Panel has enough experience and professional knowledge in the field of WPC wall panel to answer any questions you have, and George Panel has a 24-hour after-sales team. Don’t be afraid to get in touch!

Quick Quotation