MDF Wall Panels vs WPC Wall Panels: Which is Better?

Probably 50-60% of everything around us uses wood. Wood is very important. Whether it’s kitchen, entertainment, flow, etc., it is very useful in everything around us. Whenever we want to do woodworking at home, we want to do the best we can. There are two kinds of such boards that are very famous in the world today, one is MDF board and the other is WPC board.

In our daily inquiries, many friends ask us what are MDF boards, what are WPC boards, and what are the connections and differences between them?

I. What is Medium Density Fiberboard (MDF)?

Source: https://ivox.rs/en/mdf-boards/

Density board is called density fiberboard. It is made of wood fiber or other plant fiber, prepared by fiber, applied with synthetic resin, and pressed under heat and pressure.

According to its density, it can be divided into high-density fiberboard, medium-density fiberboard and low-density fiberboard. Among them, the nominal density range of MDF fiberboard is 650Kg/m³ ~ 800Kg/m³.

MDF boards are made from wood fibres, resins and waxes and compressed under high pressure and heat to form a smooth, uniform sheet. It is a material used in furniture, cabinets, etc. MDF stands for Medium Density Fibreboard. Medium Density Fiberboard (MDF) is considered much heavier than plywood. MDF is a product made of wood. To make MDF boards, softwood and hardwood residues are broken down and further converted into wood fibers.

MDF boards are made up of many fibers but can be used as a building material. It is considered stronger and heavier than particle board. Medium Density Fiberboard (MDF) will not hold rings or knots during cutting as it is more stable than natural wood.

II. What is Wood-Plastic Composites (WPC)?

Source: https://www.georgepanel.com/product-item/hollow-wall-panel/

WPC is a combination of wood fiber and plastic, representing wood-plastic composites, which is a new type of composite material that has boomed in recent years.

Wood-plastic composites can be understood or defined as composite materials made of wood flour/wood fibers and thermoplastics such as polyvinyl chloride (PVC), polypropylene (PP), polyethylene (PE) or polylactic acid (PLA), instead of the usual resin adhesive is mixed with more than 50% of waste plant fibers such as wood powder, rice husk, straw, etc. to form new wood materials, and then processed by extrusion, molding, injection molding and other plastic processing techniques to produce boards or profiles.

WPC is mainly used in building materials, furniture, logistics packaging and other industries. The board formed by hot extrusion after mixing plastic and wood powder in a certain proportion is called extruded wood-plastic composite board.

Wood-plastic composites (WPC) are a subdivision of the larger class of substances NFPC, also known as natural fiber plastic composites. In addition to wood-plastic and wood fibers, wood-plastic composites can also accommodate various inorganic filler substances or wood fibers. Cellulose-based fibrous fillers such as pulp fibers, coffee husks, bamboo, straw, etc. may not be included.

III. Comparison between medium density fiberboard (MDF) and wood plastic composite (WPC)

Medium Density Fiberboard (MDF) vs Wood Plastic Composite (WPC) |

||

Parameters |

Medium Density Fiberboard (MDF) |

Wood Plastic Composite (WPC) |

Efficiency |

MDF boards are considered less efficient than WPC boards. | WPC boards are considered more efficient than MDF boards. |

Application |

MDF is widely used to make furniture, kitchen cabinets, etc. | WPC is widely used to develop deck floors outside of houses. |

Lamination |

In MDF, lamination is considered as a vital part. | In WPC, lamination is not a critical part. |

Types |

Density boards include ultra-light density boards, fire-resistant radiant boards, and moisture-proof boards. | WPC board has no type. |

Coating Application |

Paint can be applied directly to the surface of MDF. | You will need to apply putty to the edges of the WPC before applying paint. |

Why is the efficiency lower than WPC?

MDF has poor nail-holding power. Because the fibers of density board are very broken, the nail-holding power of MDF is much worse than that of solid wood boards and particle boards. If the screws loosen after tightening, it is difficult to fix them again due to the low strength of the density board.

IV. Comparison of WPC wall panels and MDF wall panels

1. What is WPC wall panel?

Application of WPC Wall Panel in Restaurant

WPC wall panels are made of a combination of wood fiber and plastic. The result is a highly durable and weather-resistant panel that resists moisture and rot. WPC panels are available in a variety of colors and textures, including woodgrain patterns, and can be installed using a clip and rail system.

2. What is MDF wall panel?

Application of MDF Wall Panel in Dining Room

Source: https://www.housebeautiful.com/renovate-how-to-panel-wall/

MDF wall panels, on the other hand, are made from compressed wood fibers and resin. The material is strong and easy to form and cut, and MDF panels are often used for their smooth, even surface finish. MDF wall panels can be painted or covered with finishes to create a variety of finishes.

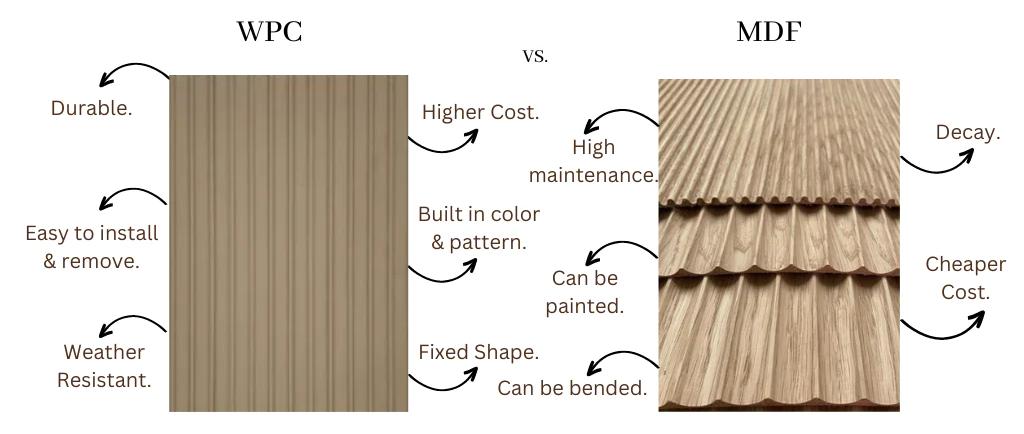

3. Comparison of WPC wall panels and MDF wall panels

Here are some key factors to consider when comparing WPC wall panels and MDF wall panels:

– Durability

WPC siding is extremely durable and weather resistant, making it ideal for outdoor or wet areas. MDF is less resistant to moisture and rot and may require regular maintenance.

– Installation

WPC panels can be installed using a clip and rail system, which makes them easy to install and remove. MDF panel installation involves nailing or gluing them to the wall.

– Aesthetics

WPC panels come in a variety of colors and textures, including woodgrain patterns, while MDF panels can be painted or covered with veneer to create a variety of finishes.

– Cost

WPC panels are generally more expensive than MDF panels, but they offer superior durability and weather resistance. WPC cost per sqm is approximately ~4400php/sqm with surface finish while MDF cost per sqm is ~2000php/sqm with paint or lamination.

– Waterproof performance

MDF panels swell when liquid or water seeps in, while WPC panels are waterproof.

– Service life

MDF boards can be used for up to 10 years, while WPC boards can be used for 50 to 100 years, with a company warranty of 25 years.

– Processing

MDF boards are not easily converted into different shapes, while WPC boards can be easily converted into other forms.

– Environmental protection

Some harmful chemicals and substances can be used in the production of MDF. However, no chemicals or hazardous substances are used in the manufacture of WPC.

V. Conclusion

Choosing the right siding material can have a major impact on the appearance and durability of your walls. Both WPC wall panel and MDF wall panel are popular options, but each has advantages and disadvantages.

Consider your specific needs and budget when making your decision, and don’t forget to explore other types of wall panels, such as MDF flex groove panels or flex batten panels, to find the best fit for your project.

Both board materials, MDF boards and WPC boards, are tested and efficient in their respective applications. It all depends on the location and how you intend to use it. However, WPC is considered more efficient than MDF. If you want quality woodwork in your office or home on a budget, then WPC is your first choice if you want to use it outside your office or residential building as it is more durable, efficient and more affordable than MDF. You don’t have to worry about water or rain falling on the WPC panels because they are waterproof.

Quick Quotation